Winch

Maintenance

Though winches don’t actually come in contact with the load, their

function of tighteningand anchoring the webbing or cable is critical to the security of

the over-the road cargo hauling.

INSPECTION

To insure winches will perform a quick inspection before each use will assure they are undamaged and working properly. Damaged or non-operational winches should be replaced immediately.

CARE

For optimum performance, winches should be cleaned to remove dirt, mud, road salt, and ice. Lubrication ensures that gravity will allow the winch pawl to drop freely into the sprocket teeth, and the sprocket will rotate freely. When not in use, portable winches should be cleaned and stored in a dry location. With a little care, your winches will go a long way.

DID YOU KNOW? About Winches

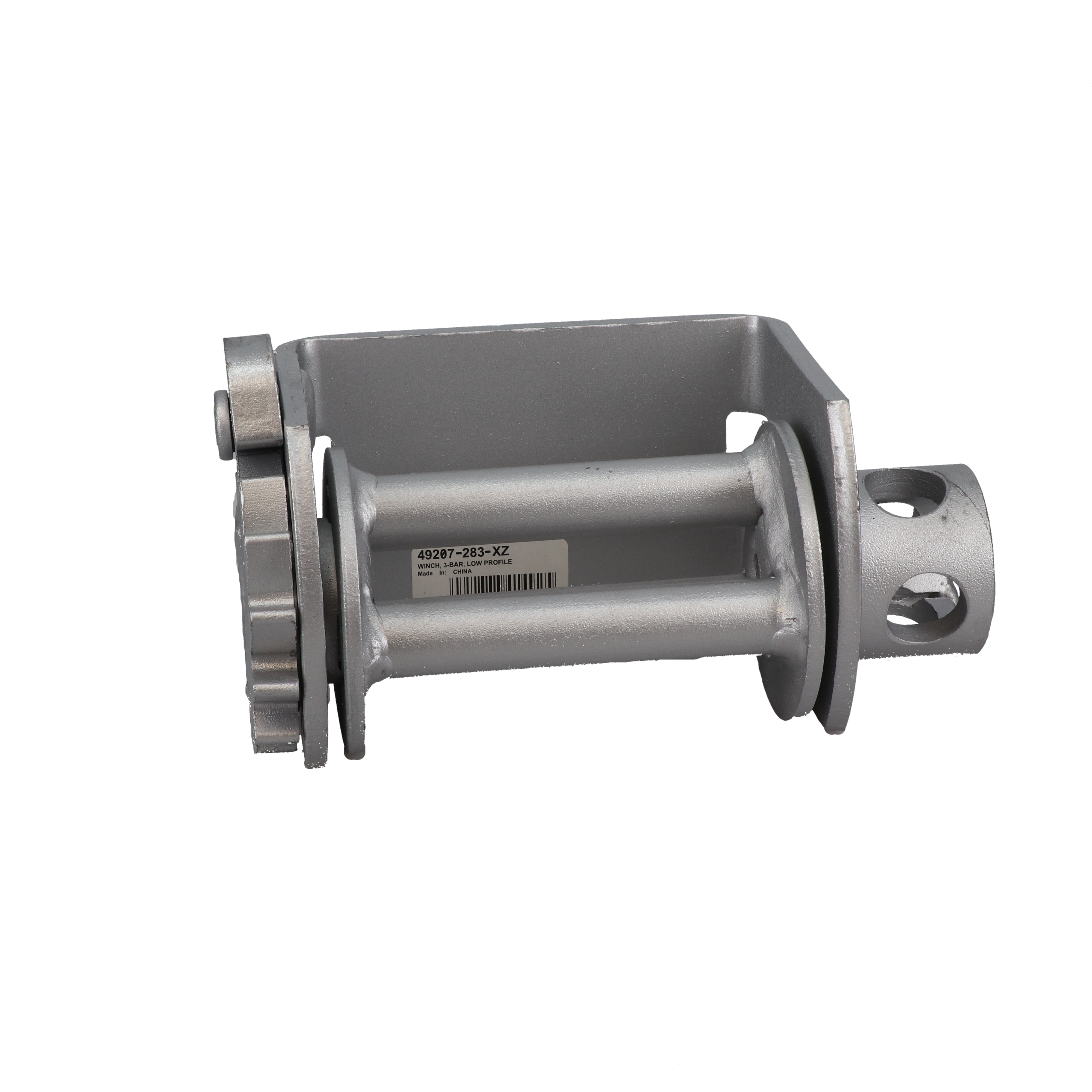

3-BAR: Designed for easy strap insertion during snow and ice conditions. Prevents the mandrel from freezing up.

PORTABLE: Versatile and meant for temporary installation, and can be placed along the trailer side frame.

SPOOL: Designed to reduce strap wear, spool discs guide and store the webbing into a single roll up to 30'.

STANDARD DOUBLE CAP: Incremental adjustment from both sides of the winch allows for clearance applications.

SLIDERS: Allow for easy positioning in the track, but lock into place when tension is applied to the strap. For use with Ancra track 42357-11, 42357-21, 49242-10-120 or equivalent.

7MM: Reduces Weight per Winch by 2 lbs. on Average. Lighter weight reduces fuel expenses and allows for a greater pay load. Heat treated material maintains strength.

RATCHETING WINCHES: Faster and more convenient than traditional winches. Reduces the tensioning time by 33%. Also, reduces risk of winch bar rollover.

X-TREME WINCHES: To give your winches a longer working life, specify X-Treme Zinc for better corrosion protection than zinc-plated, paint or powder coated finishes.

DID YOU

KNOW?

Portable and slider winches are engineered to be placed anywhere along the side of the trailer as needed to best secure the load.

WINCH OPERATION & MAINTENANCE

MAINTENANCE:

Clean and lubricate latch pawl pivot as needed to maintain a free moving latch pawl. Use rust inhibiting light oil. DO NOT use caustic or acid based cleaners on winches.

INSPECT:

Inspect before use for damage and proper working condition. Damaged or inoperable winches shall be removed from service.

WEB WINCHES:

A minimum 12 inches of webbing shall be inserted through web slot (pull excess web through). After tensioning there shall be 2 to 4 wraps on mandrel. Less wraps result in slippage and more wraps put added strain on winch. Do not use webbing binders over sharp edges, when cut, or when webbing or hardware is damaged.

CABLE WINCHES:

Refer to cable manufacturer for WLL of cable. Twist an eye in end of cable with at least 2 feet of loose tail. Place eye over pin on mandrel; tighten winch, wrapping cable over tail end at least 4 times.

PORTABLE WINCHES:

DO NOT over tighten set screws. They need to be tight enough to position winch while tension is being applied. DO NOT attach portable winches to rub rails. Remove portable winches when not in use and store in a dry location

TENSION and RELEASE:

Operator must make sure their footing is secure and load is stable before tensioning or releasing tie down. Use a winch bar inserted through both sides of the mandrel cap.

US Dollars

US Dollars

CA EN

CA EN